Press Fit Insert Specifications & Approvals

Press fit inserts are available in a variety of size and length combinations to suit your application needs. Click into the AirBus, Boeing, McDonnell Douglas, or Marketing Masters specification sheets below for more detailed information on each type of press-in product.

At Marketing Masters, we offer many different sizes of press-fit inserts to suit many different needs and aircraft panel fastener thickness requirements. Our standard press-fit insert requires a 7/16" hole to be drilled in the panel and it has a 7/8" diameter flange that will be glued to the panel skin.

For more information regarding our Press Fit Threaded Inserts, get in touch with our sales team or call us at (425) 454-5610 and we will gladly answer any questions that you may have. Marketing Masters is your trusted source for state-of-the-art press in threaded inserts.

Press Fit Specs & Descriptions

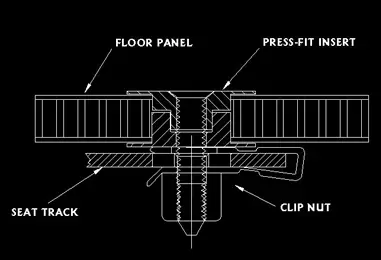

Composite Press Fit Floor Panel Inserts provide exclusive advantages to commercial airlines and many other industries throughout the world. Press-in floor panel inserts provide an excellent strength-to-weight ratio, provide advanced corrosion protection, and are less expensive than standard fastener materials.

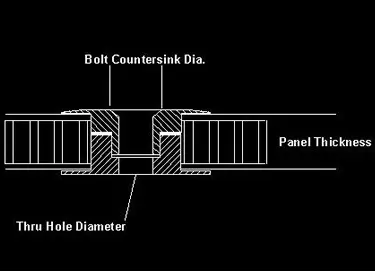

- Bolt Countersink Diameter: diameter of the countersink of the bolt in the press-fit insert.

- Panel Thickness / Length: thickness of the honeycomb panel, corresponding to the length of the press-fit insert.

- Thru Hole Diameter: diameter of the thru hole in the press-fit insert.

Press Fit Insert Styles

Marketing Masters' fastener catalog contains product descriptions, specifications, and CAD Drawings on our complete line of press fit inserts and clip nuts. When it comes to composite aircraft panel fasteners, Marketing Masters is the standard for every major airline OEM. Click logo for details on each OEM's line of Marketing Masters' Press Fit Insert Standards.

Order Composite Press Fit Floor Panel Inserts Today

For more information regarding our press in floor panel inserts, contact us or request a quote for specific pricing information today. Marketing Masters is a leading OEM manufacturer of ultra-strong, non-corrosive, light weight, and less expensive composite press fit inserts.